3M

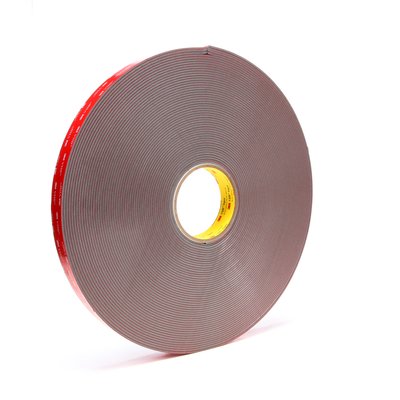

VHB™ Tape 4991

90 Mil Gray Conformable Acrylic Foam Tape

3M™ VHB™ Tape is a 90 mil double sided, conformable acrylic foam. 4991 is the main product when conformability is necessary. 4991 utilizes multi-purpose acrylic adhesive on both sides of a conformable foam. It has excellent adhesion to a broad range of high and medium surface energy substrates including metals, glass and a wide variety of plastics and plasticized vinyl. In many cases 4991 can replace rivets, spot welds, liquid adhesives or other permanent fasteners.

| Backing/Carrier | Acrylic Foam |

|---|---|

| Adhesive | Acrylic |

| Thickness | 90 Mils |

| Tensile | 60.00 lbs/in |

|---|---|

| Elongation | |

| Adhesion (liner) | 320 oz/in |

| Adhesion (unwind) | 320 oz/in |

| Min. Application Temp | 60° F |

|---|---|

| Min. Service Temp | -40° F |

| Max Short-Term Temp | 250° F |

| Max Long-Term Temp | 200° F |

Product Features

- Gray closed-cell foam carrier

- Density is 45lb./cubic ft.

- 5 mil red polyethylene film liner

- Static shear at 72°F 1/2 sq. in. holds 1,000 grams over 10,000 minutes

- 4991 is appropriate for applications, which demand a thicker conformable product

- It has a Plasticizer Resistant adhesive

- Solvent resistant

Adhesive Tape Applications

- Bond muntin bars to windows

- Bond & seal polycarbonate lens over LCD

- Bond pre-painted metals in truck assembly

- Mount vinyl wiring ducts and conduit channels

- Bond & seal plastic windows to pre-painted control panels/switch gear

- Replace rivets

- Bonding a variety of substrates, including most metal, sealed wood and glass, as well as many plastics, composites and painted surfaces

Adhesive Tape Colors

- Gray

Converting Services

Precision Cutting, Die Cutting, Slitting, Printing, Laminating and Coating, Spooling and Finishing, Consulting & Process Audit, Prototyping, Inventory Management

At Budnick, we specialize in custom converting these materials into labor saving, user-friendly parts.

Data provided by Budnick Converting, Inc.

The physical properties listed are typical values and are not to be considered as specifications. Our suggestions for use are based on tests we believe to be reliable. However, the purchaser must carry out their own tests to determine the suitability of the product for their internal use. Information is given in good faith, but without warranty.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied be clean, dry and free of grease and oil.

Shelf life from date of manufacture is based on the product being stored at 70°F(21°C) / 50% relative humidity out of direct sunlight.

Specification compliance is dynamic and should only be used as a general guide. Always confirm that the tape you are interested in currently complies with all specification requirements. Please verify that the product number that you select is available in the proper size and color to meet your specification.