Slitting

Budnick's multiple slitting capabilities across several machines produce the highest quality converted rolls for each of your diverse applications, whether you need ultra-thin .03" rolls or wide width rolls for laminating, we have the flexibility to slit a wide assortment of materials regardless of their raw dimensions.

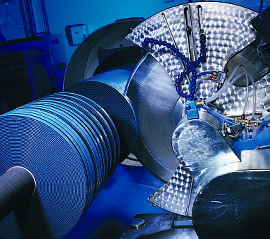

Lathe Slitting

Lathe slitting involves spinning large log rolls of adhesive tape while a computer-guided blade slits rolls to your desired width

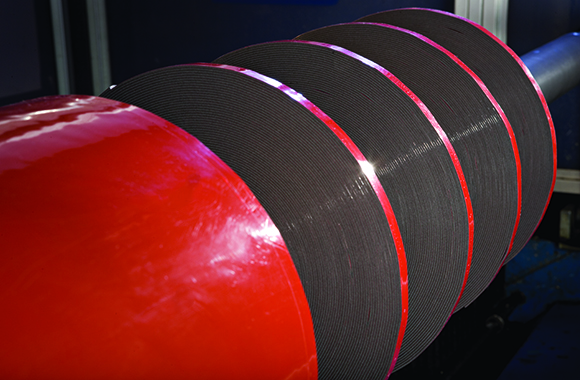

Rewind Slitting

Rewind Slitting involves unrolling a large master roll of material through a series of strategically placed blades and rewinding rolls into your specified width and length.

What We Offer

Lathe Slitting

Lathe slitting allows Budnick to quickly create slit rolls in specific, non-standard widths to meet the needs of your application. State-of-the-art lathe slitters enable operators to program blade direction, blade speed, and mandrel speed. Computerized controls ensure that every roll of product is slit to meet your exact specification, holding tight tolerances most other converters cannot match.

The electronic microprocessors control working functions for accuracy and repeatability on every roll, making sure that your products adhere to our strict quality standards with each cut.

Rewind Slitting

Winding a large master roll through a series of razor, shear or score blades while rewinding the customized width rolls to a specified length gives a new level of flexibility and efficiency to your engineering and production departments. Extremely narrow or non-standard widths allow your design engineers the freedom not available when working with a small catalog of standard products and sizes. Also, longer machine length pancake rolls reduce downtime in your production process.

Case Studies

With proprietary processes creating cleaner more precise cuts thinner than others are capable of producing, Budnick's slitting solutions have helped numerous customers across a huge variety of industries. Read below to learn about some of our solutions!

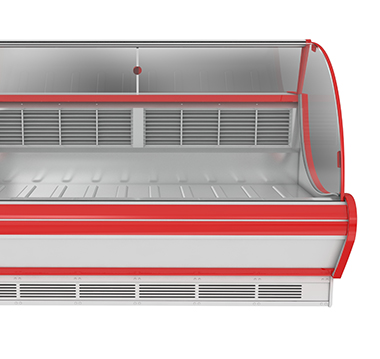

Projector Screen Reflection Reduction & Window Shade Extrusion Mounting

A projection screen and window shade manufacturer needed an adhesive tape laminated to flock material and a tape that would bond extrusions to window shades.

- Customer’s previous supplier sent unusable, wrinkled material

- Needed an adhesive tape to laminate to flocked material

- Budnick laminates a double coated tape to the flock and slits it into rolls with zero quality issues

Case Study Small Changes

A customer was using a high tack adhesive for numerous applications throughout their process - but there were issues with some having exposed adhesive.

- Multi-use tape was used for several applications and redundant on use

- After the tape was applied, adhesive was exposed in some areas

- Customer continued with a single product that would fit all the existing applications

Electronic Device Repair Die Cuts

Budnick's narrow width slitting and die-cutting capabilities enhanced this electronic device repair company's efficiencies when repairing Apple Watches

- Customer's previous converter could not consistently slit to narrow widths

- Budnick recommended switching to a tape that is much more ideal for bonding applications within electronic devices

- Various die-cut shapes and sizes presented on a single pad sped up production time and eliminated the use of unsafe cutting tools