Case Study - Attaching Stiffener Bars to Computer Enclosures

Customer Need

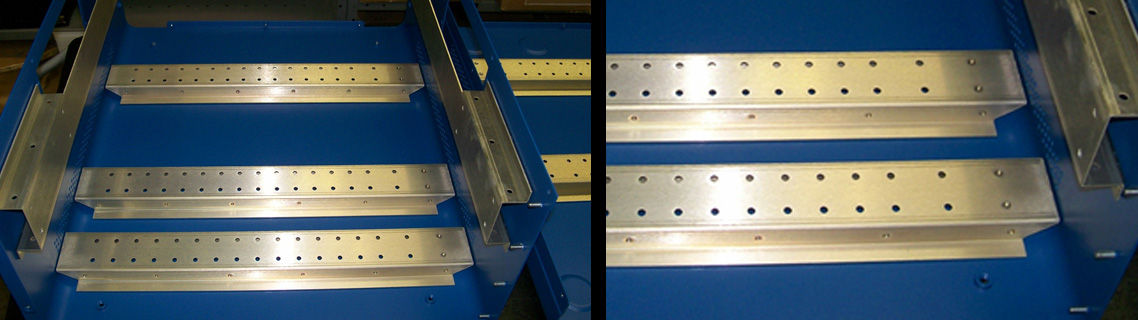

We often find that customers are looking to simplify and enhance their mounting applications. In this instance, an electronics manufacturer needed an alternative method to mount stiffener bars to computer boxes. The customer had previously been using spot welds to attach the stiffener bars. In addition to timely prep steps required before the weld, it was not aesthetically pleasing, nor was the assembly easy.

The Budnick Solution

Budnick recommended using 3M™ VHB™, a high bond foam acrylic, to replace the weld. To ease assembly, we die cut the VHB™ into strips and created a jig to help hold the parts in place during placement. 3M™ VHB™ was chosen due to its ability to bond to powder coated paint and the need for a softer, more conformable foam due to imperfections in the metal.

Enhanced Productivity

The customer no longer has to outsource the welding and the VHB™ eliminated many of the prep steps. Pre-drilled holes are no longer necessary and the VHB™ withstands the powdercoat painting process. The custom die-cut strips reduced the time required for assembly and handling, saving the customer production time.