Laminating and Coating

Adhesive lamination and coating allow you to create custom adhesives that fit your project's specific needs by applying almost any adhesive to nearly any substrate.

Laminating

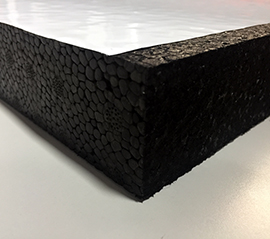

Budnick can quickly laminate adhesive to one or both sides of rigid and flexible foams, rubbers, plastics, textiles, FRP panels, and many other materials in one pass.

Coating

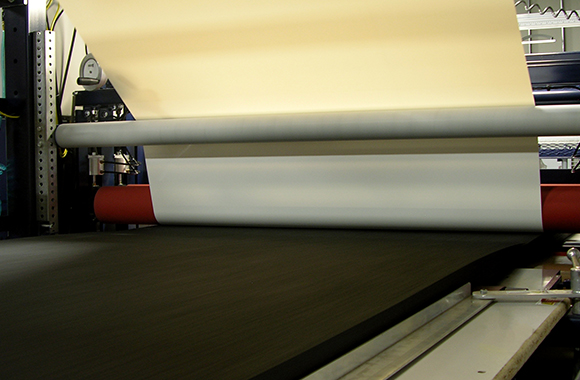

Adhesive coating is an economical way to create custom patterns of adhesives and can be done inline with other processes to create custom shapes or add features like finger-lift liners.

What We Offer

Adhesive Coating

This process applies a precise thickness of either permanent or removable adhesive to your material. Your specifications determine the coating thickness necessary for optimal performance. Adhesive coating is also a way to create custom patterns of adhesive, including irregular shapes, lanes, and ungummed areas - meeting whatever production requirements you may have.

Lamination

Our 60-inch wide heat laminating system allows us to laminate one or both sides with adhesive and cut sheeted materials in a single pass. We can quickly laminate adhesive to rigid and flexible foams, rubbers, plastics, textiles, FRP panels, and many other materials.

Case Studies

Budnick has created custom adhesive products for a wide range of applications to improve the process and performance of products across a variety of industries.

Case Study Adhesive Tab

This customer came to Budnick requesting our help in creating an adhesive tab matrix with easy application onto a film.

- The tab needed to stick quickly in a temperature range from 0 – 150°F

- Tab required bondability to both sides of the film

- The tab would be part of a product used to collect crops while in the fields

Case Study Quick Response

A commercial refrigeration manufacturer needed to protect commercial coolers from the time they were on the production floor to installation.

- Customer was looking for a product to act as a bumper on the commercial coolers

- Bumpers needed to withstand high temperatures while being transported in train cars

- The bumpers would be applied to metal surfaces and needed clean removability

Case Study Vendor Value

A customer was seeking a less expensive, alternative that would have to bond to a wide variety of veneer backings.

- The large veneer and edge banding manufacturer had been using an acrylic transfer

- A double coated acrylic tape with a paper liner was chosen and slit to size

- The anti-slip liner gave the customer an opportunity to brand their product