Die Cutting

Budnick die cuts adhesive tapes, foams, and other flexible materials to a variety of custom shapes and sizes that can be provided as individual parts, in sheet form, or on a roll. Our rotary, flatbed, laser, and waterjet processes deliver tight-tolerance parts optimized for automated assembly or manual application.

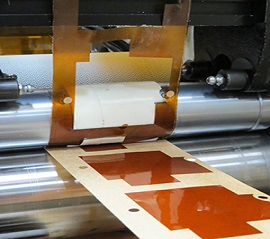

Rotary Die Cutting - Narrow Web

Precision-engraved steel cylinders die-cut, kiss-cut, butt-cut, or cavity-cut a wide variety of rolled goods including adhesive and non-adhesive tapes, foams, foils, fabrics, films, and more into production-ready parts.

Rotary Die Cutting - Wide Web

Up to 30" wide web processing simplifies and accelerates production of large, complex die-cut parts. Laminate and convert multiple materials in a single pass to reduce costs and improve part quality.

Flatbed Die Cutting

Flatbed die-cutting helps save money on tooling and accommodates thicker and softer material than most rotary methods allow. This process is ideal for shorter but still intricate production runs.

Specialized Capabilities

Advanced equipment allows us to minimize scrap and maximize runtimes and production efficiency - from longer length rolls and finger lift edges, to reduced scrap by spacing parts without a matrix.

Budnick's Die Cutting Processes

With a multitude of different processes, we have the versatility to die cut almost any material to customer specifications & tolerances. Each machine and operator have different qualities that line up with individual customer needs.

Our narrow and wide web rotary presses allow us to provide individual parts or parts on rolls or sheets, while holding the tightest of tolerances.

The flatbed department can work with difficult materials and still provide the edge quality and product consistency to meet your specifications. Flatbed processing is better suited for thicker and/or denser foams. Flatbed tooling is less expensive which reduces costs on smaller volume jobs. With over 70 pieces of converting equipment, we typically have the process to improve the quality of your parts and reduce the processing time to save you money.

Budnick Die Cuts: Tape | Pressure Sensitive Materials | Silicone Rubber | Fabric | Label Stock | Plastic Liner | Plastic | Gasket Materials | UHMW | Foil | Non-Woven | Foam | Silicone Foam | Abrasive | Specialty Materials | Rubber & More

Case Studies

Budnick has developed a series of proprietary die-cutting processes that lead to cleaner, more accurate cuts. Read on to learn how else we've improved our customers' processes!

Case Study Enhanced Production

Lacking in production efficiency and healthy hands, this aerospace came to Budnick in search of solutions for a complex masking application.

- Workers were cutting tape by hand and often cutting themselves

- Tape was being cut for various sizes of metal parts to mask during shot peening

- After working with Budnick, the customer was able to double production

Electronic Device Repair Die Cuts

Budnick's narrow width slitting and die-cutting capabilities enhanced this electronic device repair company's efficiencies when repairing Apple Watches

- Customer's previous converter could not consistently slit to narrow widths

- Budnick recommended switching to a tape that is much more ideal for bonding applications within electronic devices

- Various die-cut shapes and sizes presented on a single pad sped up production time and eliminated the use of unsafe cutting tools

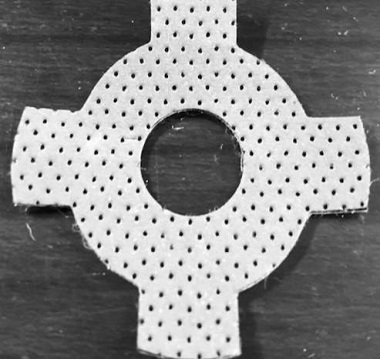

Conductive Die Cut Gasket for Electrical Grounding

A major appliance OEM needed an electrical grounding solution due to quality issues with wiring/lighting.

- Worked with 3M™ to provide products for testing

- Provided a die-cut gasket with electrically conductive properties

- Quick and easy to apply