4 Reasons Why You Should Be Using Spooled Rolls of Material

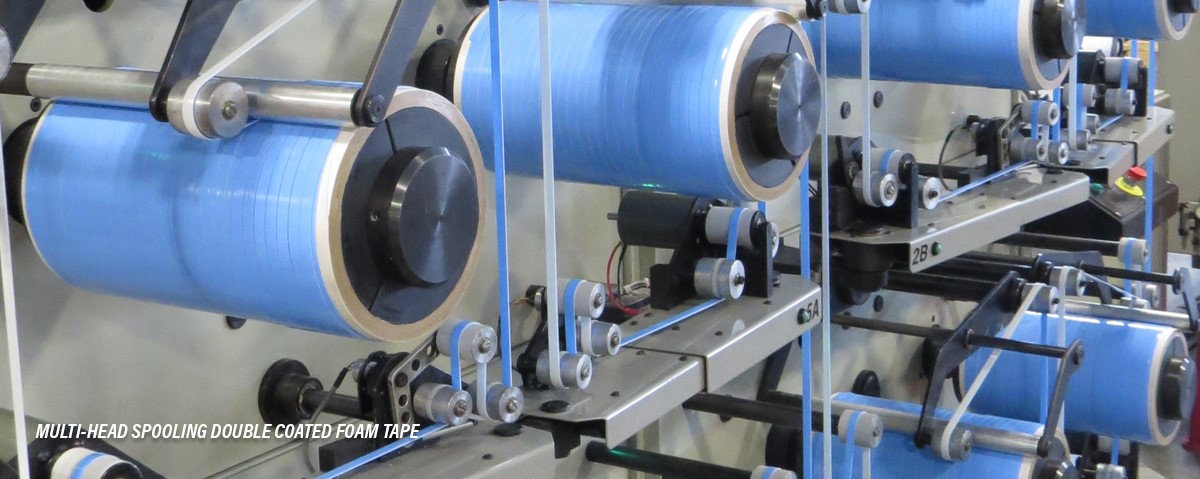

Traverse wound spooled rolls of material can eliminate the need for individual rolls and reduce the amount of waste that is generated. Here are four ways Budnick's spooling services can improve your efficiencies and increase production.

-

Increased yield: Spooled rolls allow you to use more of the material that you have purchased by reducing the amount of material that is lost due to scrap or trimming. As a result, you can produce more finished products with the same amount of raw material

-

Improved handling: Spooled rolls are easier to handle and transport than individual rolls. They are wound tightly onto a spool, which makes them more compact and easier to store.

-

Consistent quality: Spooled rolls can help to ensure consistent quality throughout your production process. The spool ensures that the material is wound tightly and evenly, which can reduce the likelihood of defects or variations in the finished product.

- Less downtime: Traverse wound spools reduce the amount of material that is lost due to starting and stopping your production equipment. As a result, you can produce more finished products from your raw material.

Budnick can spool rolls three times as wide as most competitors and as narrow as .1''. Contact us today and speak with our converting experts about your spooling needs.