Custom Adhesive Tape Solutions Help Automotive Manufacturers Meet the Latest Trends and Design Demands

The need for safety, weight reduction, ease of assembly, low VOC’s, noise reduction, cold shock, and high temperature masking have driven improved tape and converting technologies. Specialty converters, like Budnick, are now providing custom cut tapes for everything from trim attachment to water sealing gaskets. Custom designed and converted parts improve quality and speed up assembly.

Attachment

High bond tapes permanently attach emblems, trims, moldings, appliques, mirrors, headliners, lens assemblies, and much more. Whether you need solutions to withstand paint ovens or cold shock resistance, tapes can get it done.

Low VOC Tapes

With increasing governmental regulations regarding the interior air quality within new vehicles, tape manufacturers continue to adapt with low VOC tapes. Budnick carries low VOC tapes for interior trim attachment, seat mounting, cockpit components, sealing and gasketing.

Weight Reduction

Pressure to improve fuel mileage is greater than ever for automotive manufacturers. No longer can manufacturers solely rely on downsizing to reduce weight. Budnick meets the demand for lightweight materials with foams and tapes that provide solutions for trim attachment, seating, emblem mounting, dashboard mounting, and more. In addition to reducing weight, these tapes and foams decrease the spread of fire, lower toxicities, and provide sound and vibration damping.

Increased Productivity

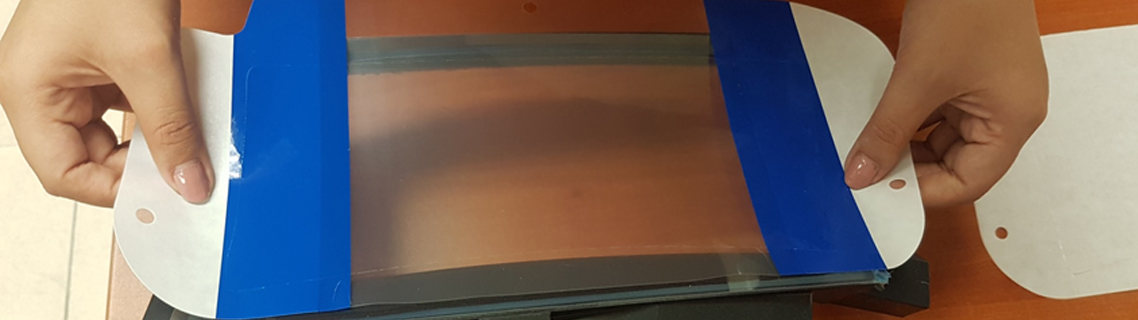

Custom converted adhesive products reduce assembly and rework time. Whether it’s die cutting surface protection films to exact dimensions or implementing die-cut masking products that improve paint quality while reducing masking/de-masking time, the Budnick team can help automotive manufacturing processes.

Click here for Budnick's complete selection of adhesive tapes for the automotive industry