Waterjet: Cutting What Can't Be Machined

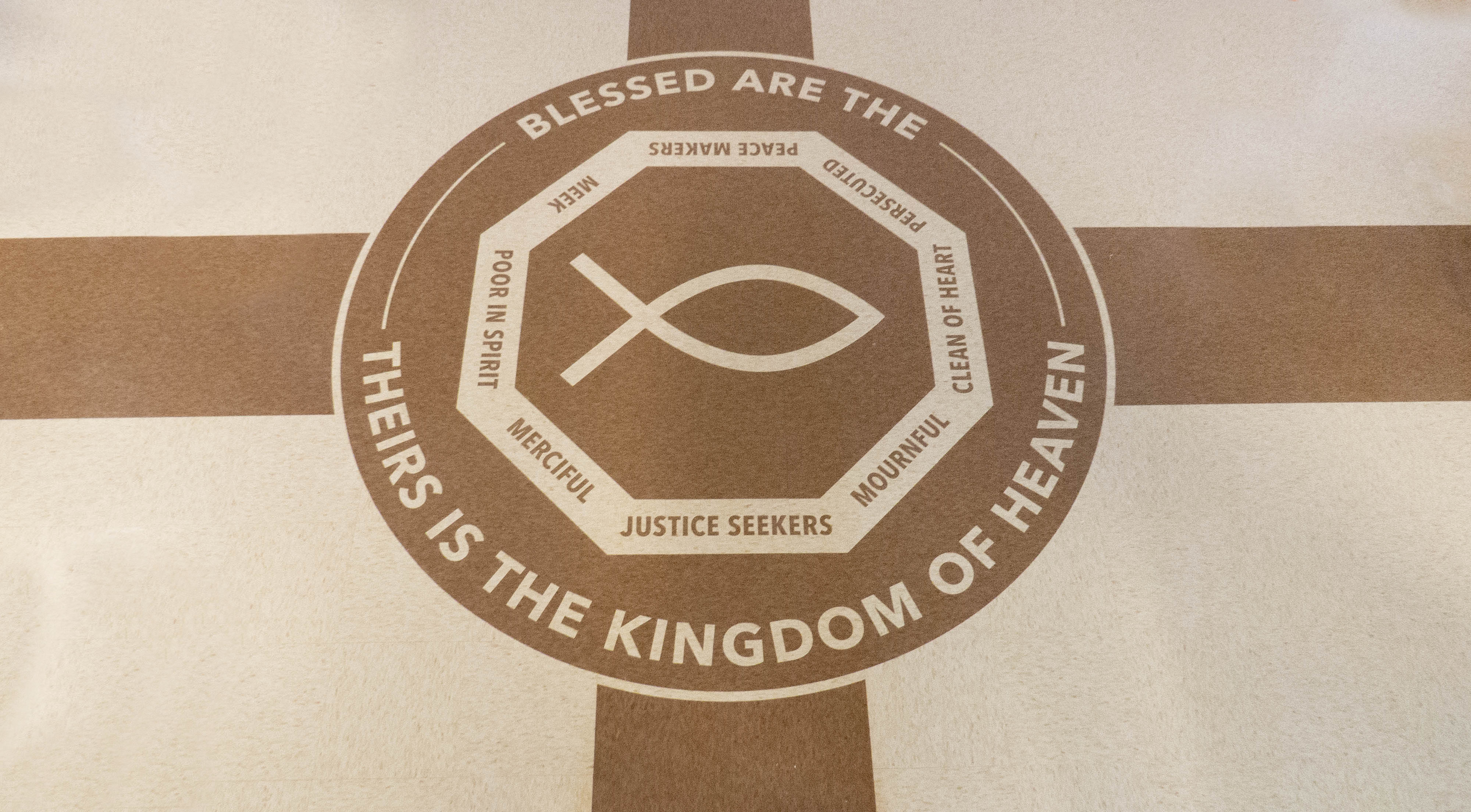

When Immaculate Conception built their new church & school in Columbia, IL, they wanted an inspirational message at the intersection of all their school hallways. They turned to Budnick to Waterjet cut this gorgeous inlay VCT flooring.

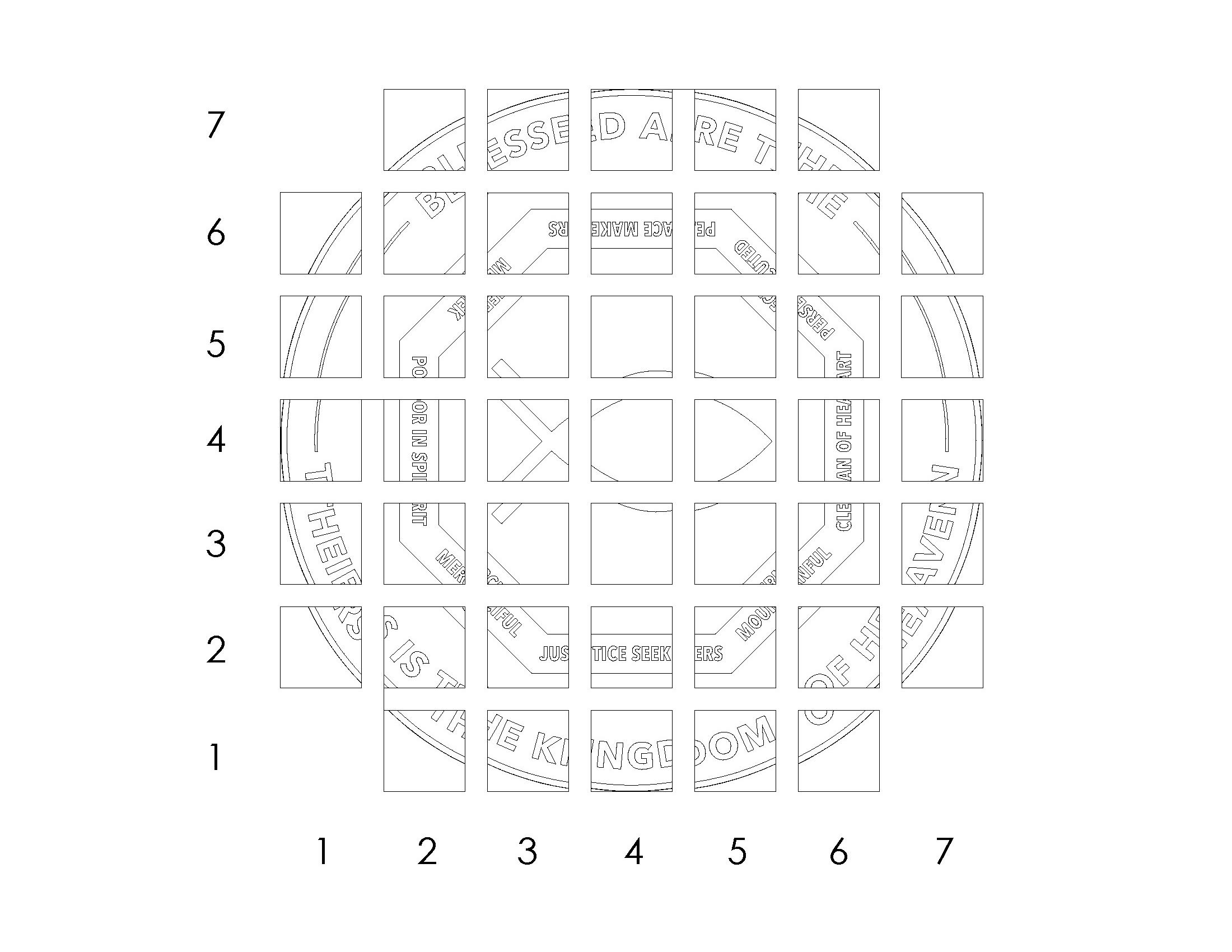

The Budnick team offered the local church a 50% discount on Waterjet Converting services. They also saved countless installation hours by providing precision cut materials that fit together just as designed. To save installers time, the Budnick team also labeled each part, packed them in an organized manner, and provided an installation diagram (shown below).

Budnick team members were proud to help inspire and beautify our local community.

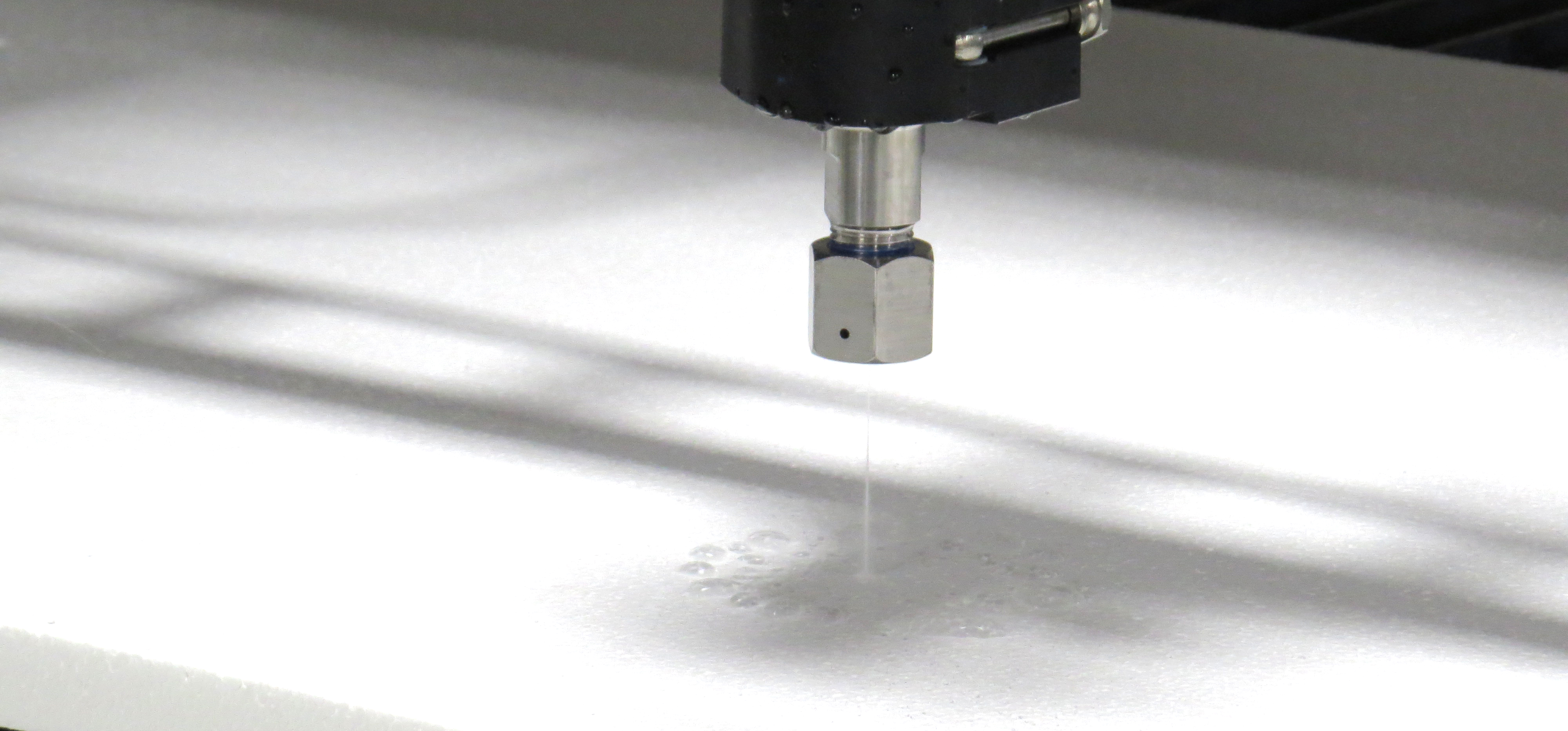

Waterjet/Abrasivejet Cutting Process

Today’s engineers need the design freedom to maximize space utilization while creating cost effective products. To succeed, they need both materials and fabricating processes to meet stringent tolerance requirements. When selecting the proper cutting method, you must consider the material composition, thickness, tolerances, quantities per run, finished part presentation, and many other factors.

Waterjet is a great solution for thicker foams and parts that require very intricate cuts while eliminating the thermal stress issues affecting some materials during the laser cutting process. Waterjet cuts are made with an ultra-high pressure stream of either water or garnet and water. The stream is computer numerically controlled (CNC) to precision cut almost any material.

Waterjet machines can:

- cut what can’t be machined, by cutting materials such as laminates, stones, composites, and most metals, without fracturing, chipping, or thermal stress.

- maximize material yield by often cutting along common edges with almost no waste

- produce quality parts by cutting them to tolerances as tight as +/- .005” – perfect for inlay parts

Benefits:

- Improves product quality

- Eliminates most finishing operations

- Reduces tooling costs

- Exceptional fit of inlay materials

- Easy dimensional changes

- Maximizes material yield

- Saves installation time

Materials: Adhesive Tape | Laminates | Textiles | Leather | Gasket Material | Cloth | Vinyl | Reflective Materials | Films | Polycarbonates | Aluminum | Brass | Plexiglass | Polystyrene | Particle Board | Heat Sensitive Materials |Porcelain | Steel | Granite | Plastic | Cardboard | Linoleum | Muntz | Pavers | Ceramic | Rubber | Cloth | Carpet | Stone | Kevlar | Tile | Foam | Paper | Wood | VCT | Glass | Marble | Titanium